A continuous wire is fed to the work piece. Table: Submerged arc welding vs mig welding Spray arc welding vs mig Spray arc welding Mig welding Molten metal droplets are transferred through the arc Only electric spark is passed through the gap between electrode and the surface of workpiece Used for thicker metals or butt joints Used for thin metal sheets Table: Spray arc welding vs Mig welding Shielded metal arc welding vs mig Shielded metal arc welding Mig welding Conventional arc welding process which uses a flux to shield the weld. The comparison between submerged arc welding and metal inert gas welding is shown in the table below Submerged Arc welding Mig welding Uses continuous feed wire Uses continuous feed wire Uses powdered flux for shielding Uses inert gases like Helium for shielding Fully automatic Semi automatic Used for only down handing welding It can be used in various positions Used for very thick metals Used for thin plates. The comparison between gasless mig vs arc welding is given in the table below Gasless mig welding Arc welding No gas is required for shielding No shielding is required Better for both thin and thick sheets of metals Better for thick sheets for metals The set up is expensive The set up is cheaper than gasless mig Table: Gasless mig vs arc welding Submerged arc welding vs mig welding Mig welding Arc welding The welding is stronger on thinner materials The welding is weaker for thinner materials The welding is weaker on thick materials The welding is stronger for thick materials Table: MIg VS Arc welding strength Gasless mig vs arc welding The table below shows the difference between mig welding and arc welding strength. The strength of welds are different for different welding processes. The arc flows through this short distance. An arc is formed when there is high voltage passing through the electrode and the electrode is lifted by a very small distance from the work piece disconnecting the circuit. The heat generated from the arc is used to join the two metals. There are four types of arc welding which are been discussed in the later section of this article. A consumable or non consumable electrode can be used in this process.

The arc is generated by an AC or DC supply. Image credits : Weldscientist, RK WL GMAW, CC BY-SA 4.0 What is Arc welding?Īrc welding as the name suggests uses an arc to fulfil the purpose of welding.

A weld bead is formed which is allowed to cool at room temperature. The arc generates enough heat to create a weld pool in the surrounding area. The tip of the electrode is the place where arc takes place.

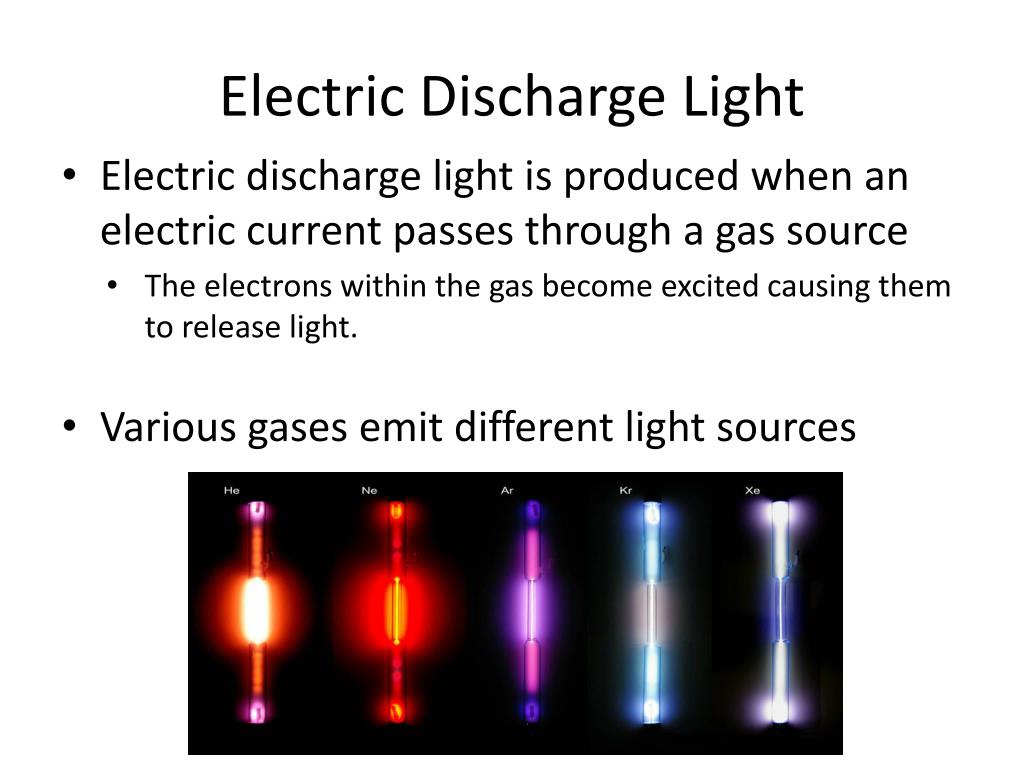

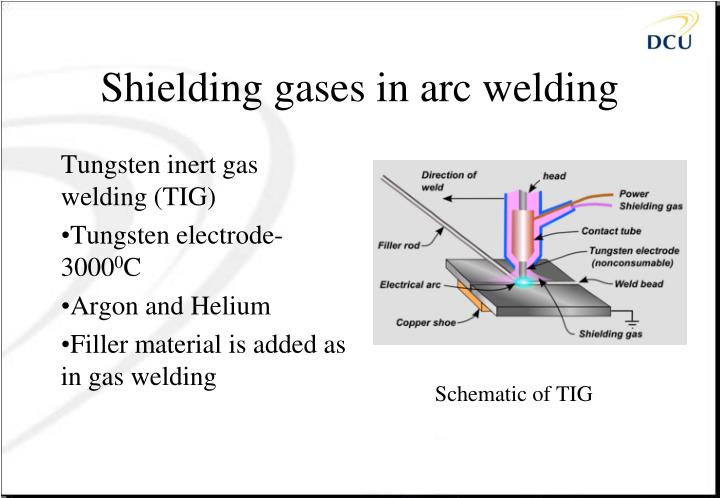

The welding takes place as a result of arc striking the surface of the work piece. Helium protects the weld pool and the bare wire electrode. As the name suggests, this type of welding includes the participation of inert gas like Helium. Mig welding stands for Metal inert gas welding. Different applications require different types of weld properties, so the sources of heat may be changes in order to make the welding process economical and energy saving. If any one of the parameters is not properly regulated then the weld formation will not take place properly and the weld may break due to weakness. An optimum amount of both these parameters are needed to provide the weld of desired properties. This is done with the help of heat and pressure. Welding is a fabrication technique used to join two or more metals. Let us start our discussion with the definition of welding. In this article we shall focus on two kinds of welding namely mig welding and arc welding. Different amount of heat and pressure will result in welds of different properties. Welding is a fabrication technique in which two or more metals are joined together with the help of heat and pressure.ĭifferent sources of heat provide different amount of heat at the joint. This article discusses about the topic mig vs arc welding.

0 kommentar(er)

0 kommentar(er)